- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

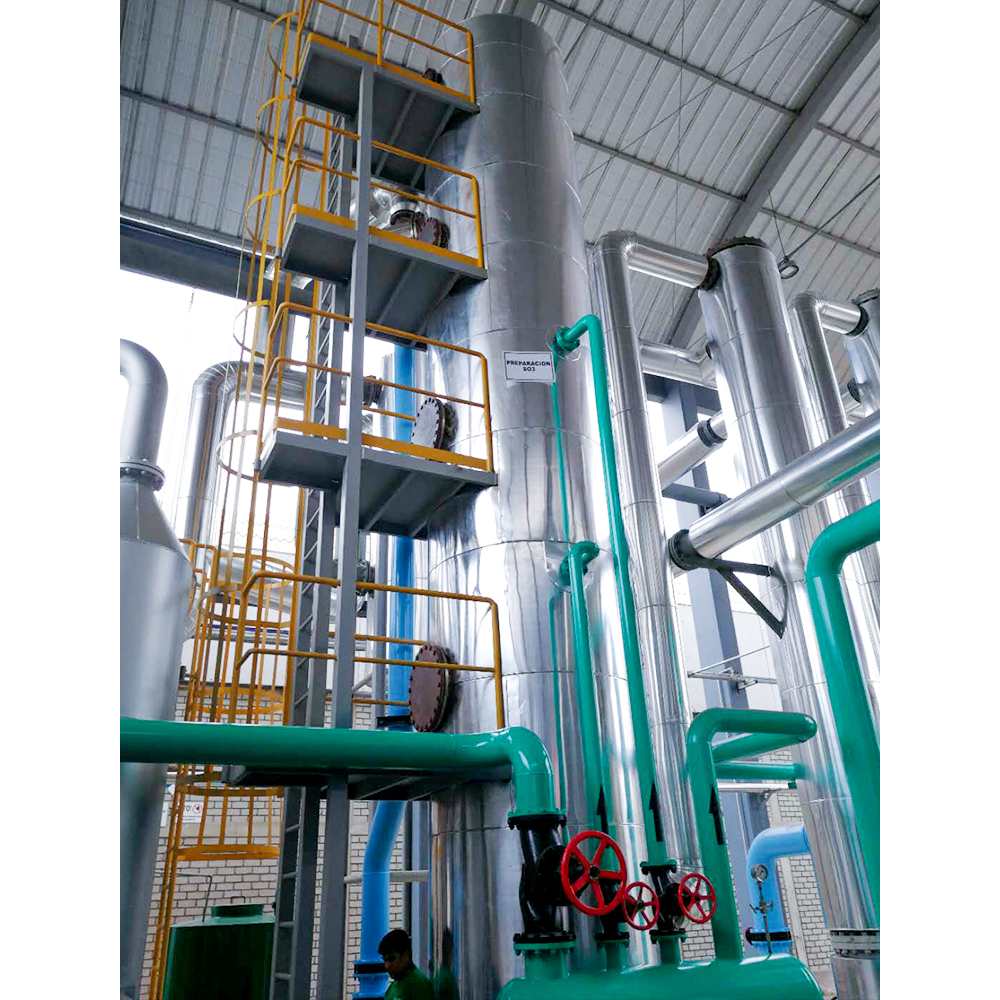

Conversion tower has a set of independent preheating systems, which are preheated by the oil furnace. The catalyst of each layer is heated in the conversion tower to desired temperature.

A built-in cooler is used for SO2 conversion reactor, which can reduce the resistance of the conversion reactor. The loading amount of the catalyst is improved in the conversion tower, so that when a reasonable filling ratio of the catalyst in each layer is distributed, a high conversion rate can be obtained given a guaranteed catalyst quality.

Heat exchanger inserted between first and second layer of the converter is used for controlling the reaction temperature, while other part of the reaction heat is cooled directly by mixing with drying process air. The conversion rate of SO2 can reach more than 98% with the function of conversion tower.

Conversion tower has a set of independent preheating systems, which are preheated by the oil furnace. The catalyst of each layer is heated in the conversion tower to desired temperature.

A built-in cooler is used for SO2 conversion reactor, which can reduce the resistance of the conversion reactor. The loading amount of the catalyst is improved in the conversion tower, so that when a reasonable filling ratio of the catalyst in each layer is distributed, a high conversion rate can be obtained given a guaranteed catalyst quality.

Heat exchanger inserted between first and second layer of the converter is used for controlling the reaction temperature, while other part of the reaction heat is cooled directly by mixing with drying process air. The conversion rate of SO2 can reach more than 98% with the function of conversion tower.